There is good reason for the increased attention in the news over the past few months about the lung disease Silicosis. Not to be taken lightly, the disease has afflicted a number of people in a wide range of industries throughout Australia and around the world, and has even caused death.

Certainly, it is time for businesses in the mining, tunnelling, quarry and stonemasonry industry to get a clear understanding of their legislative obligations, as soon as possible. There are many practical actions you can take now to start working towards preventing this disease in your workplace.

A great starting point is to first learn about the nature of the disease, in terms of the hazards and risks, which predispose workers to the condition. It is important to understand that silicosis is entirely preventable.

What is silicosis?

Silicosis is a lung disease caused by breathing tiny airborne particles of silica – also known as silica dust – into the lungs.

As the particles are inhaled they have the potential to penetrate and scar the lung tissue, causing it to become stiffer over time dependent on the duration of exposure and intensity of silica exposure (in terms of the workplace). This prevents the lungs from transferring oxygen into the blood stream properly and can lead to a number of health impacts, including irreversible lung damage, autoimmune disease and premature death.

Yet silicosis is a very varied disease, with different levels of risks and health complications. It can develop after a few weeks or even up to a few years after exposure to silica dust. Indeed, different types of silicosis – such as acute silicosis, accelerated silicosis, or chronic silicosis – all develop in different ways and exhibit different symptoms.

The risk of developing silicosis – with faster progression – increases as the intensity of exposure intensifies.

Additionally, it should be noted that there are a variety of other diseases and health conditions related to exposure to silica, such as chronic bronchitis, emphysema, lung cancer and tuberculosis.

It is important to remember that there are often no symptoms at all in the early stages of the disease. So, it’s not wise to believe that simply because no one is coughing, everything is fine.

Over time, shortness of breath and coughing are signs of the disease, or another related disease as listed above, may be developing. This can continue to deteriorate over time, impacting a person’s ability to work, perform simple and low impact activities of daily living and to breath at all.

Who is at risk?

Silica dust finds its way into the lungs of workers in a variety of industries, as they perform many of the most common and everyday tasks related to those job roles.

Cutting, grinding, crushing, drilling, sawing, excavating, chiseling, paving, surfacing, polishing… if you use any of these types of words to describe what you or your workers do, it might be time to consider the risks associated with silica dust in your workplace.

You might think of those cutting artificial stones first following the media attention, or people working in mining. Certainly people in these industries are at risk. Yet, consider other industries that regularly perform these tasks that you may not think of initially – landscaping, building, stone masonry, or pottery and ceramics.

Clearly, the possibility of silica dust affecting the workforce can be widespread across more than one industry.

Where can silica be found?

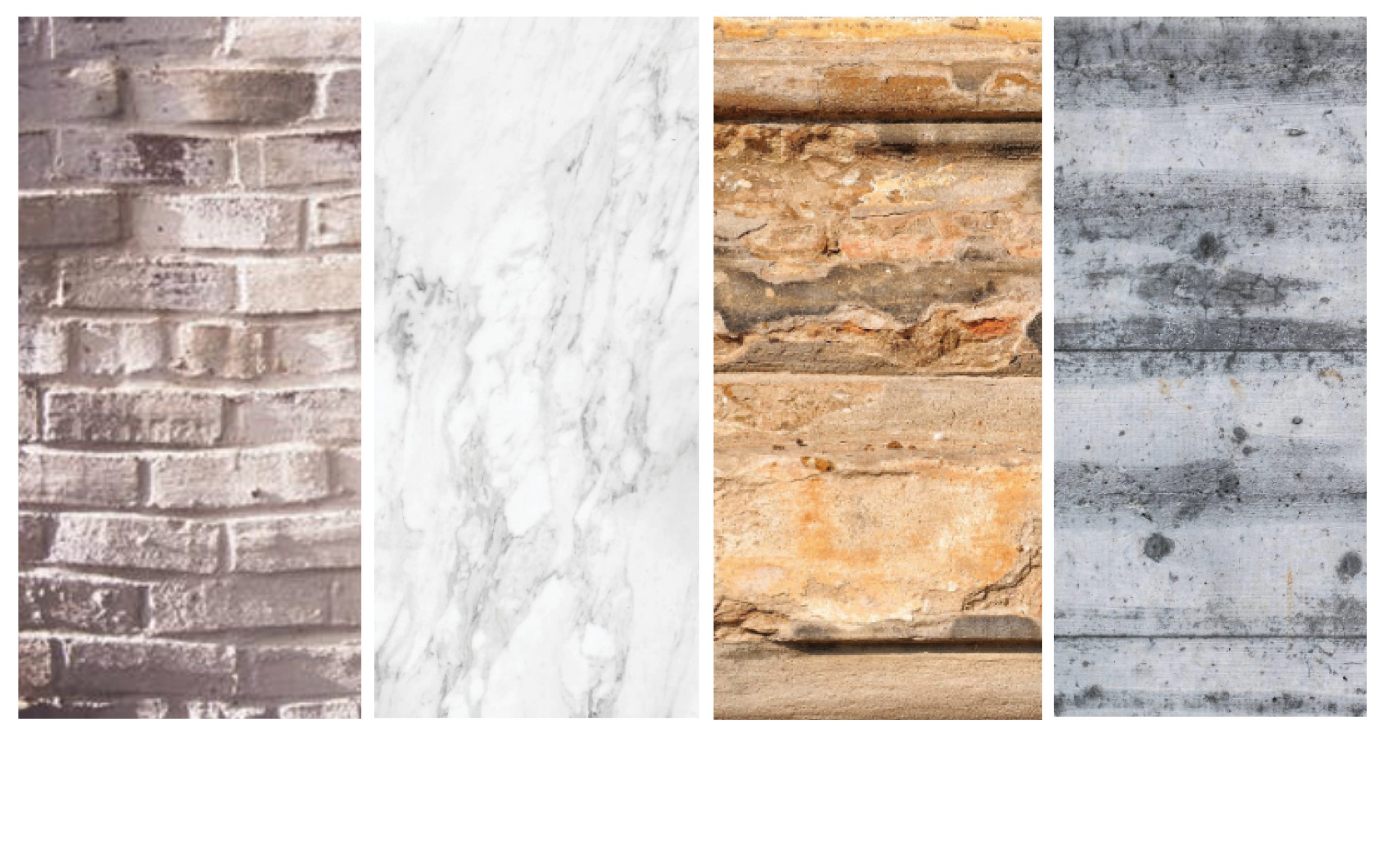

Make no mistake, this issue is not only related to workers that cut composite stone for a living. Silica is found in all kinds of stone – natural or otherwise – concrete, mortar, brick, tilers and some plastics.

Despite what many people think, silica (SiO2) is actually a naturally occurring mineral. It is the main component of sand and 95% of natural rock. But it is also used to make a variety of artificial or engineered stone products.

The significant hazards and risks associated with manufacturing and/or working with artificial or engineered stone is the high crystalline silica content (i.e. greater than 85%).

The table below lists the common stone products and their typical crystalline silica content.

| Reconstituted stone (eg, Caesarstone, Quantum Quartz, Smartstone) | More than 90% |

| Sandstone | 70% to 90% |

| Granite | 25% to 40% |

| Slate | 20% to 40% |

| Marble | Less than 5 % |

Source: WorkSafe Victoria

Practical controls you can put in place

Silicosis is an entirely preventable disease. As such, the controls and measures that each of us put in place in our workplaces have the potential to make significant positive impact to ensure that this disease does not continue to impact Australian morbidity and/or mortality rates in the workforce.

Prevention is key. Starting at the top of the hierarchy of controls, here is some practical advice:

| Substitution | Source composite stone with a lower percentage of crystalline silica |

| Isolation | Enclose areas with dust generating tasks and implement suitable extraction systems that reduce dust exposure in the workplace. Use automation where possible. |

| Engineering | Minimise the risk of exposure to generated silica dust, with local exhaust ventilation, water suppression (wet cutting), and/or using the correct tools which have inbuilt extraction and water generating capacity. |

| Should a risk still remain after implementing substitution, isolation, and engineering controls, consider; | |

| Administration | Ensure site rules, policies and procedures are suitable and appropriately implemented and managed in your workplace – consider shift rotations and effective training and induction processes. |

| PPE | Ensure that all personal protective equipment is fit for purpose; respiratory equipment (minimum of a P2 efficiency half face respirator) with fit-test processes in place and work clothing that either does not collect dust, or is appropriately laundered or disposed of in the workplace. |

Additionally, regular and thorough dust monitoring and worker health surveillance is an important and critical part of the process.

Action OHS Consulting Pty Ltd can support businesses to identify the degree of the problem in their workplace(s) and support the contextualisation of suitable and appropriate risk control measures to address the hazards and risks in the workplace.

Plus, WorkSafe Victoria has compiled some invaluable resources with industry-specific advice about Silicosis. Have a read: https://www.worksafe.vic.gov.au/crystalline-silica

What are your legal responsibilities?

It goes without saying that as an employer, you must provide a safe workplace. What does this involve?

- Appropriate pre-employment checks;

- Health surveillance for workers with potential exposure to silica dust;

- Worker consultation and communication;

- Implementation, monitoring and review of suitable and appropriate risk controls in accordance with the hierarchy of controls and contextually relevant to the specific hazards and risks in the relevant workplace.

Victorian AmendmentsIn Victoria, the Occupational Health and Safety Regulations 2017 were amended 20 August 2019 to provide greater protection to Victorian employees working with engineered stone. Engineered stone as manufactured composite stone that contains resins and has a crystalline silica content of at least 80 per cent. Engineered stone is commonly used as kitchen, bathroom and laundry bench tops. These amendments now prohibit uncontrolled cutting, grinding and abrasive polishing of engineered stone with power tools. |

What does this really mean?It means that all controls must be properly designed, installed, used and maintained so they stay effective at reducing exposure to crystalline silica dust. |

What are the controls you must be across?

If these controls are not reasonably practicable, the use of power tools must be controlled through local exhaust ventilation (LEV).

|

Air and health monitoring – yes or no?Employers continue to have an obligation to carry out air monitoring if they are not sure if their employees are exposed to levels of silica dust that are above the exposure standard – i.e. 0.02 mg/m3 a time-weighted average (TWA) airborne concentration over 8 hours. With respect to this monitoring, employers should carry it out on a regular basis to ensure employee exposure is controlled. Employers should carry out health monitoring in all workplaces there is exposure to airborne silica, unless air monitoring data shows that exposure is less than 0.02 mg/m3 as a time-weighted average (TWA) airborne concentration over 8 hours. |

If you don’t comply?If you are not able to comply with the requirements for cutting, polishing or abrasively polishing engineered stone with power tools, the work cannot be done. Failing to control risks of dry processing may be a criminal offence. |

If you require assistanceYou should call us. As a Victorian-based Health and Safety Consulting business, we have the knowledge and capability to support you manage your regulatory needs. If you are a business with less than 60 workers, the OHS Essentials Program is something you should consider to ensure that you remain knowledgeable about silica and your legislative duty. |