Prosecutions: 2018 Summary for NSW & Victoria

Workplace prosecutions are something that health and safety practitioners, and business leaders alike should maintain current awareness of. Why? Because due diligence is all about collecting information to better understand impacts to a business’s operation, to allow better and more informed decisions being made. The intention; in this instance, to prevent negative situations of the past being repeated.

For the fourth year in a row, Action OHS Consulting has taken some time to collate and review the data available from WorkSafe Victoria and SafeWork NSW. Used effectively, the provided information should support you to influence key stakeholders within your organisation, and assist your business to make informed decisions with respect to their health and safety program.

This article provides an overview of the prosecutions from 2015 through to the 2018 calendar years.

Prosecutions: Numbers and Related Legislation

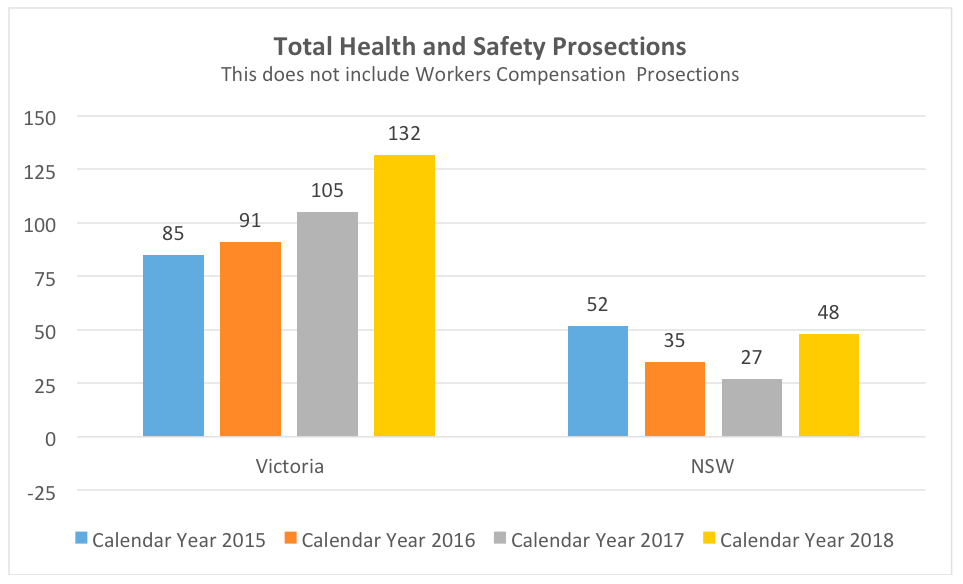

Calendar Year 2018 saw a total of 132 prosecutions against the Victorian health and safety legislation, whilst in NSW the number of prosecutions was 48. When compared to the previous year, there has been a 26% increase in Victoria and a 71% increase in NSW. When compared to the average of the 3-years prior, there was a 40% increase in Victoria, and a 26% increase in the prosecutions that have occurred in NSW.

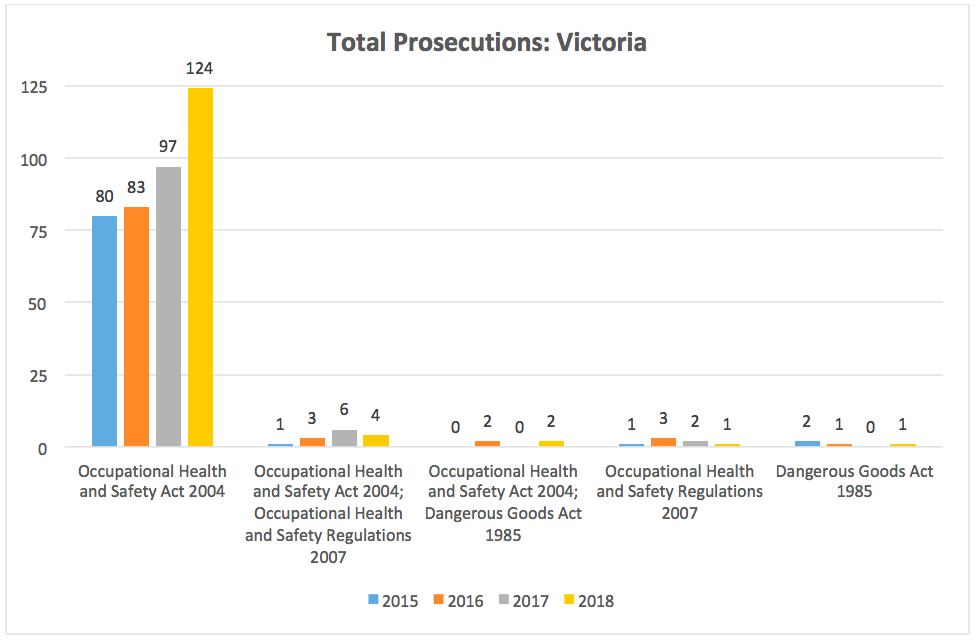

Within Victoria:

- 124 prosecutions were recorded against the Occupational Health and Safety Act 2004

- 4 prosecution involved both the Occupational Health and Safety Act 2004 and the Occupational Health and Safety Regulations 2007

4 prosecution involved either the: (i) Dangerous Goods (Transport by Road or Rail) Regulations 2008; (ii) Dangerous Goods Act 1985; or, (iii) Dangerous Goods Act 1985, Occupational Health and Safety Act 2004

While 2017 saw the introduction of the updated Occupational Health and Safety Regulations 2017; with prosecution timeframes on average over 2-years, the outcomes from prosecutions against the updated regulations are likely to become visible from 2019 and beyond.

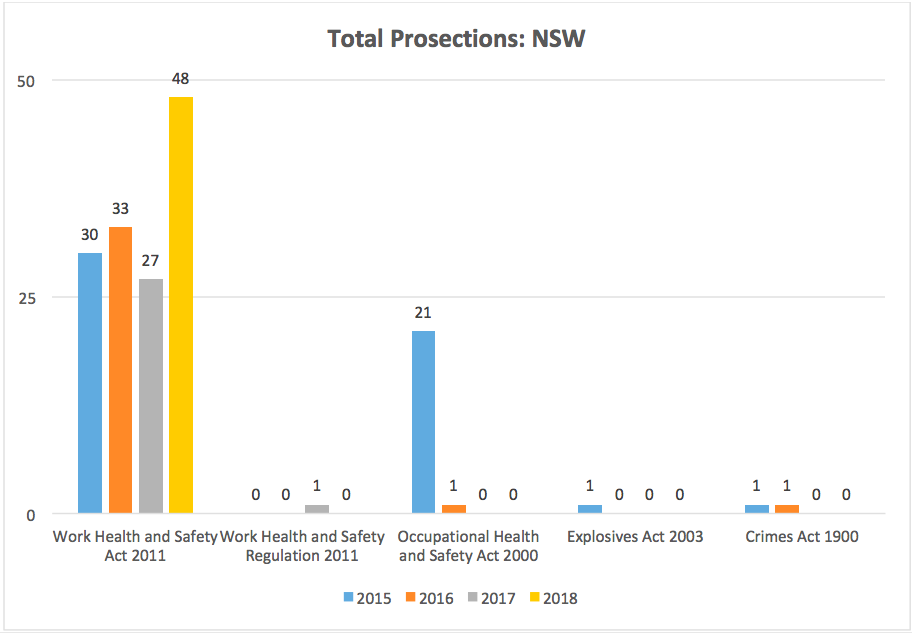

Within NSW:

- All 48 prosecutions were recorded against the Work Health and Safety Act 2011.

Following the last prosecution against the Occupational Health and Safety Act 2000 being in 2016, and with their being no prosecutions in 2017 or 2018, this may signal a complete transition in NSW to prosecutions against the harmonised legislation. Note the Occupational Health and Safety Act 2000 was superseded as of 1 January 2012.

Prosecution Timeframes

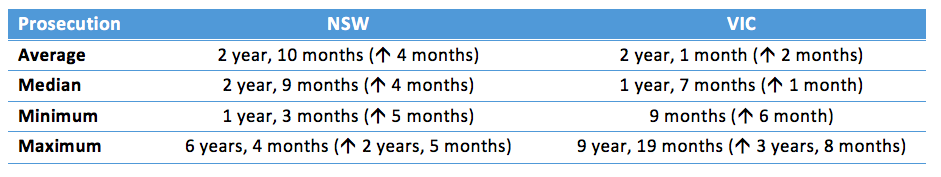

The timeframe for the prosecution’s outcomes from 2018, when measured against the date of the offence have been listed in the table below.

Table 1: Timeframe between date of offence and the prosecution outcome, for the 2018 prosecution outcomes reported by SafeWork NSW & WorkSafe Victoria. Bracketed numbers represent the increase / decrease from 2017.

When compared year-on-year, prosecution timeframes increased across all statistical definitions that were reviewed. The increased length in prosecution time will have an impact on business operations, as incident closure will be delayed. In addition to the prosecution, this is likely to impact both person- and financial resources. The reason for the increased time was not assessed.

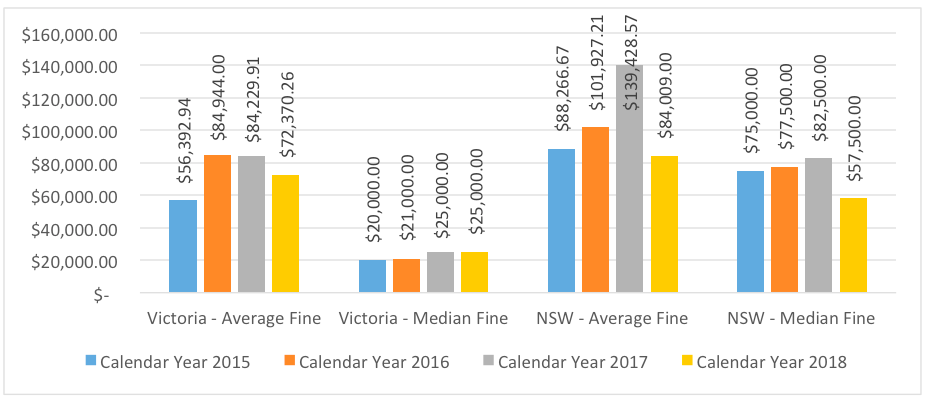

Health and Safety Fines

Year on year, the average fine and median fine decreased in NSW. In Victoria only the average fine decreased, with the median fine staying at $25,000. The average and median fines were greater in NSW, when compared to Victoria. However, there were 2.5 times more prosecutions in Victoria.

In NSW each prosecution resulted in a monetary fine. In Victoria 114 fines were issued (87% of prosecutions). When considering total costs (e.g. court costs, court funds, etc.) all prosecutions against the Occupational Health and Safety Act 2004 had a financially impact.

In addition to the fines, WorkSafe Victoria issued 6 Enforceable Undertakings in 2018 which equates to 5% of prosecutions. This is compared to the 6 (7%), 7 (8%) and 10 (7%) Enforceable Undertaking issued in 2015, 2016 and 2017 respectively. An enforceable undertaking is a legally binding agreement between WorkSafe Victoria and the employer. The employer is obliged to carry out the specific activities outlined in the agreed undertaking. EU’s will typically guide and direct the business being prosecuted to improve its health and safety program.

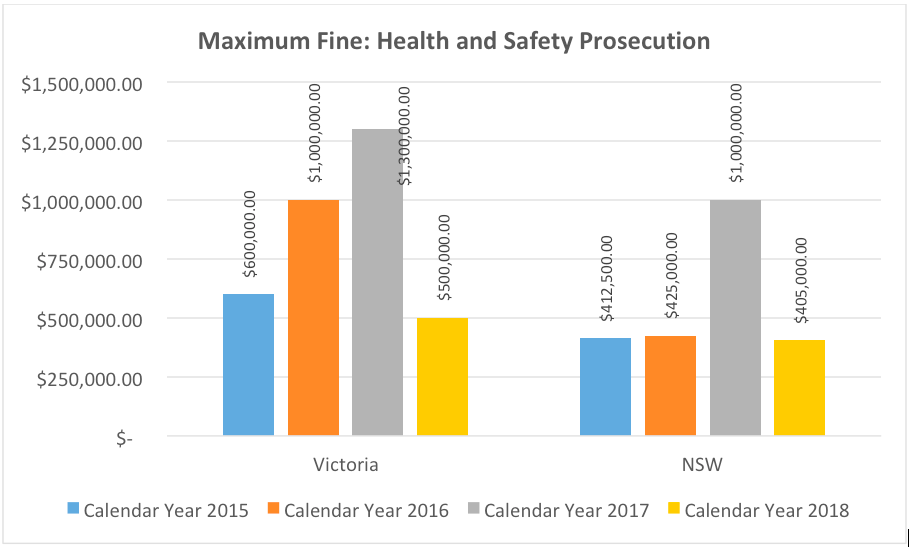

Health and Safety Fines: Maximum Issued

With respect to fines, the maximum fines for both Victoria and NSW decreased year on year.

The maximum fines issued to a business were associated with the following events:

- Victoria: The business provided high volume concrete pumping services to the construction industry. On the morning of the incident, the Operations Manager at the workplace directed employees to disassemble a concrete pumping component known as the ‘tower tube’ to enable it to be loaded by crane onto a truck for transportation (the task). The tower tube was approximately 15 metres long and was capable of being split into sections. The sections were held together with bolts. Each separate length of the tower tube weighed about two tonne. The task required loosening the bolts holding the lengths together whilst the tower was horizontal on the ground. In order to get access to certain of the bolts, the employees used a forklift to slightly elevate the tower. One employee took up position in the cabin of the forklift, whilst two others stood in front of the tower tube. The tynes were lifted and the tower tube slid off the tynes and struck one of the employees, trapping him against an adjacent brick wall. The forklift operator then repositioned the tynes to move the tower tube off the employee. The employee who was 28 years old sustained fatal crush injuries. The offender failed to provide a safe workplace in that the use of the forklift for this task was inherently dangerous given the nature of the load being lifted, and that a crane should have been used instead. The offender allowed its employees to improvise a system where it should have provided a system of work for splitting the tower tube (Charge 1). Further, it failed to provide instruction in that safe system of work and supervise its employees to ensure that a forklift was not used for the task (Charge 2). The offender pleaded guilty and was convicted and fined $250,000 in relation to charge 1 and fined $250,000 in relation to charge 2.

NSW: A worker was fatally injured when he fell 2.9 metres onto a concrete slab while installing a walking platform between roof trusses. The defendant was charged with a breach of section 32 / 19(1) of the Work Health and Safety Act 2011. On 26 March 2018, the defendant was convicted by the District Court and fined $405,000.

With respect to both prosecutions, it confirms the requirement for organisations to supervise and manage the work of their employees

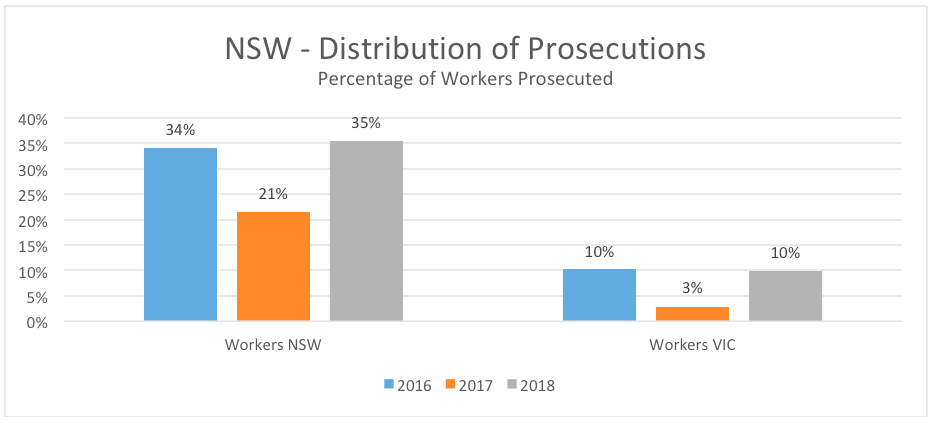

It is not just businesses that are being prosecuted in relation to health and safety breaches

If you were of the belief that health and safety prosecutions were limited to corporations – think again. In 2018, 10% and 35% of prosecutions were issued to workers in Victoria and NSW respectively – equating to 13 and 17 prosecutions respectively. This is an increase in the distribution of worker related prosecutions from 2017. With respect to the greater prosecutions in NSW, this is likely to be associated with the explicitly defined due diligence duties placed on Officers (see Section 27-5 of Work Health and Safety Act, 2011).

An overview of the prosecutions related to workers in NSW and Victoria are as follows.

In NSW there were 17 workers prosecuted, with a maximum fine of $42,000 (in this instance the business was also fined $210,000). The prosecutions were associated with the following events:

- A worker suffered crush injuries when the contents of a shipping container fell on him while he was unloading the container. The director defendant fined $12,500. The corporate defendant was fined $75,000.

- A worker was injured when he was hit by a swinging branch cut from a tree causing him to fall approximately 11 metres from the roof of a house. The defendant was convicted and fined $20,000.

- Over a 4-month period workers were exposed to a risk of serious injury in the operation of a self-contained wood-processing unit. The manufacturer’s built-in safety device had been removed and modified to permit an operator to use the handles with one hand instead of two. Those modifications were known to each of the three defendants. The defendants were convicted and the two (2) individual defendants were each fined $32,000. The corporate defendant was fined $160,000.

- A worker was seriously injured when he fell approximately 5 meters from a roof when the temporary edge protection he leant on gave way. The director was convicted and fined $5,500. The corporate defendant was fined $75,000.

- A 27-year old excavator operator, and a 54-year old plumber suffered serious injuries while attempting to repair a ruptured natural gas line. The plumber operated an electric jack hammer near the rupture which ignited the natural gas. The plumber was convicted and fined $2,200.

- The defendant produced a document in complying or purportedly complying with the WHS Act and the WHS Regulation that the defendant knew to be false or misleading. The defendant was convicted fined $9,000 in total.

- A renderer was working on a mobile scaffold when the mobile scaffold tipped and he fell approximately two metres. The defendant was convicted and fined $5,000, for not providing information pertaining to the incident. The corporate defendant was fined $20,000.

- The defendant failed to comply with an issued Improvement Notice and as such was convicted and fined $2,000.

- A machine operator suffered amputation of four fingers when she was using an unguarded industrial pillow filling machine. The defendant was convicted and fined $7,500, and ordered to complete 24 hours of training. The corporate defendant was fined $60,000.

- A tree being felled at a private residence fell in an uncontrolled manner, causing significant damage to the roof and front façade of a neighbouring house. The defendant was convicted and fined $16,500.

- An asbestos roof was water blasted as part of a painting contract at a residential property by the defendant and his brother. The water blasting contaminated the property and neighbouring properties with friable asbestos. The defendant was convicted and fined $18,000.

- Over a 1.5 year period, a development undergoing construction had failed to address WHS issues arising from incomplete scaffolding, poor housekeeping and inadequate site security. The defendant was convicted and fined a total of $42,500. The corporate defendant was fined $210,000.

- A worker was fatally injured when the asbestos roof sheeting of the warehouse he was working on broke, causing him to fall approximately 8.7 metres to the ground. The defendant was convicted by the District Court and fined $7,500. The corporate defendant was fined $75,000.

- A worker fell approximately 3 metres headfirst from an unprotected edge at a construction site. The defendant was convicted and fined $24,000. The corporate defendant was fined $120,000.

- A 25-year apprentice suffered serious injuries when he was moving a 530 kg air conditioning unit down the stairs with other workers when they lost control and the unit fell on him. The defendant was convicted and fined $7,500.

- A worker suffered serious injuries to her hand when it became trapped in a manual cup folding machine that she was operating. The defendant was convicted and fined $25,500. The corporate defendant was fined $157,500.

This is compared to Victoria there were 13 workers prosecuted, with a maximum fine of $100,000 (in this instance the business was also fined $210,000). The prosecutions were associated with the following events:

- The offender, a partner of a partnership which operated a residential and commercial construction business. A first-year apprentice and employee was standing on the external top plate of a partially constructed residence at a height of approximately 4.1 meters pulling up roof battens which were leaning on the wall frame. A safe work method statement had not been prepared prior to the high-risk work commencing and there was no fall protection such as a trestle scaffold in place. There was a risk of serious injury or death to employees as a result of a fall from height of more than two metres. The employee pulled up two of the roof battens at a time using both hands. The battens are about 6 m long. The employee put one down and grabbed one. He pulled it up approximately 500 mm and felt it scrape the top of the bearer and fall to the ground. The employee lost his balance and fell, landing on the bearers. The employee sustained several injuries including an L1 fracture in his back. The offender pleaded guilty and was without conviction sentenced to pay a fine of $10,000 and to pay costs of $2,512.05

- The offender is a registered electrician. The offender was responsible for instructing a first-year electrical apprentice. On four separate occasions over an 8-month period the apprentice was tasked with work which required the isolation, disconnection and reconnection of power. This was work that should have been undertaken under direct supervision by a qualified electrician. There was a risk of death or serious injury to the first-year apprentice as a result of working unsupervised. The offender failed to take reasonable care as he did not supervise the apprentice when the apprentice was undertaking work involving isolation, disconnection and reconnection of power including power point installation, installing hardwired smoke detectors, replacing a Tastic light and repairing a hot water service. The offender pleaded guilty and was without conviction sentenced to pay a fine of $4,000 for Charge 1, $4,000 for Charge 2, $4,000 for Charge 3 and $4,000 for Charge 4 and to pay costs of $1,000.

- The offender was the secretary, sole director and sole owner of a business who completed structural drawings for the basement excavation works for a mixed commercial and residential development. The offender was the structural engineer for the development. The structural drawings for the workplace did not require the concurrent installation of a site retention system. There was a risk to persons working inside, or working, residing or travelling in the vicinity of the excavation pit that, if the walls of the excavation collapsed, they could be seriously injured or killed by being engulfed in the collapse, or falling into the excavation pit. Sometime during the night part of the excavation collapsed in the workplace. On another night a further, and much larger, collapse occurred. In order to reduce the risk of collapse it was reasonably practicable for the offender to prepare structural drawings that required the concurrent installation of a site retention system that involved the installation of bored piers around the perimeter of the excavation before excavation commenced, the installation of rock anchors and the progressive installation of sprayed concrete infill panels until the required depth of excavation was reached. The offender pleaded guilty and was with conviction sentenced to pay a fine of $100,000.00.

- The offender is an officer of the partnership engaged to demolish two single storey buildings at Prahran. A 55-year old employee was working as a labourer at the workplace. The offender was operating an excavator to clear the site. There was no designated walk area identified by barriers or pedestrian walkways to separate employees from the excavator when it was operating. There was a risk of serious injury or death as a result of the operating excavator colliding with employees. The employee was working behind the excavator when it started to reverse. The employee did not hear any reversing beeping noises from the excavator and yelled out to the offender when it came into contact with his leg, at which stage the excavator stopped moving. The employee received injuries to his right leg requiring surgery. The offender pleaded guilty and was without conviction sentenced to pay a fine of $5,000 and to pay costs of $3,000.

- The offender was undertaking the building of six multi-level townhouses and was the architect, builder and owner of the project. The offender engaged contractors to perform building works at the workplace, including works in and around the internal stairwell voids of the multi-level townhouses. The offender failed to provide a proprietary scaffold system with a solid construction base and the capacity for perimeter handrails or an engineered temporary platform with a solid construction base and the capacity for handrails. The offender also failed to provide a Safe Work Method Statement (SWMS) that identified the risks of working at a height of greater than two metres and provided for suitable control measures. This created a risk to persons working in, or moving through the internal stairwell voids, that they could fall from a height that was greater than 2 metres, and that if they fell, they could be seriously injured or killed. A plastering subcontractor was standing on the temporary scaffold. The plastering subcontractor stood on the temporary scaffold for approximately 20 seconds, when it collapsed, and he fell approximately 2.5 to 3 metres to a concrete floor. The plastering subcontractor suffered a fractured heel, two compression fractures in his spine and assorted abrasions. The offender pleaded guilty and was without conviction sentenced to pay a fine of $20,000 and to pay costs of $15,064.

- The offender was a Director of a company granted a licence as a Class B Asbestos Removalist. The company’s licence was renewed in 2007 for three years, and again in 2010 for five years, with an expiry date of 21 January 2015. In 2015 WorkSafe received an application for renewal of the licence. WorkSafe wrote to the company advising that its application for renewal had been refused and provided its reasons for this decision. It was established that following the notification by WorkSafe in 2015 that the company’s licence was not being renewed it had carried out asbestos removal work at 6 properties without being licensed to do so. The offender pleaded guilty and was without conviction, sentenced to an adjourned undertaking to be of good behaviour for 12 months and ordered to pay $3,300.00 to the Court Fund and to pay costs of $2,200.00.

- The offender and sole director of a residential carpentry and construction company was engaged by a principal contractor to manage and undertake carpentry works at a construction site where 3 two storey units were being built. An apprentice carpenter was assisting in the installation of pre-fabricated roof trusses at a height of approximately 3 metres from the ground. The employee was working from a 200 mm aluminium plank which was positioned on two external walls. There was no passive fall prevention device in place such as scaffolding and this was attributable to the offender’s failure to take reasonable care. There was a risk of serious injury to employees as the result of a fall from height of more than two metres. The employee stepped back from the plank onto what he thought was the top plate; however, there was nothing there, and he fell backwards to the ground. The employee was diagnosed with compression fractures in L2 and L3. The offender pleaded guilty and was convicted and sentenced to pay a fine of $20,000 and to pay costs of $2,383.

- The offender provides long haul transport services across Australia. The offender was engaged to transport mixed goods from Sydney to Melbourne. The goods contained dangerous goods. The truck was captured by CCTV approaching the Domain Tunnel eastbound. As the truck approached the tunnel, it stopped in an emergency lane. The offender exited the passenger side door and turned a “Dangerous Goods” placard around. He then re-entered the passenger side of the truck which then entered the Domain Tunnel. The offender pleaded guilty and was without conviction placed on a 12-month adjourned undertaking to be of good behaviour.

- The offender runs a demolition business and had been engaged to demolish a single storey weatherboard dwelling. A WorkSafe Inspector attended the address and observed two persons working at the workplace. The Inspector observed asbestos containing material (ACM) had been demolished and had been placed in the back of a utility without any lining or wrapping. Broken sheets of ACM lay under the veranda. The two workers telephoned the offender who attended the workplace. The Inspector issued a cease work direction and issued a Prohibition Notice to the offender. A clearance certificate was issued that day for the removal of ACM in the utility. The Inspector re-attended the workplace and observed a licensed asbestos removalist had been engaged to complete the asbestos removal. Further asbestos was located and subsequently removed. A clearance certificate was provided. Investigation revealed that the offender had successfully completed a course in ‘Remove non-friable asbestos’; however, he did not have an asbestos removal licence. The offender pleaded guilty to one charge as a person carrying out asbestos removal work without being licensed or registered. He was sentenced, without conviction, to a 12-month adjourned undertaking and ordered to pay costs of $3,406.60.

- The accused was a 72-year-old woman who was the owner and operator of a scrap metal business. The accused had management and control of the workplace. The workplace is a second-hand goods and scrap recycling business which is owned and operated by the accused. There was a forklift at the workplace which the accused drove. She had never held a forklift licence as required by the OHS Regulations 2007. The accused was transferring scrap metal from inside a 1.8 metre metal bin into a larger 6 metre metal bin. The deceased was positioned inside the smaller bin which had been raised to approximately 3 metres from ground level by the accused operating the forklift. The 1.8 metre scrap bin that the deceased was standing in was not secured to the forklift or the forklift tynes. The bin raised on the tynes had only one channel (instead of the required two) on its base. The bin was not engaged at all with the tyne of the forklift, including with the one available channel. No attempts were made to secure the bin to the forklift. This bin was also in very poor condition with holes and corrosion in various locations. The forklift tynes were not spread as wide as they could be and were not central on the mast of the forklift. The task was also being carried out on uneven ground with a slight incline. There was a risk of death or serious injury to persons in the vicinity of the forklift, from being struck by the object and/or forklift. Further the conduct of raising the bin containing scrap metal on the tynes of a forklift, that was not secured to the forklift with the deceased inside the bin was reckless conduct that endangered another person who was at the workplace. The risk eventuated when the deceased fell from the bin, with the bin also falling from the tynes of the forklift where the corner of the bin land on the deceased’s head killing the deceased. The offender pleaded guilty and was on charge 2 convicted and sentenced to pay a fine of $10,000 and on charge 3 convicted and sentenced to 6-months imprisonment. Costs were also ordered in the sum of $7,336.

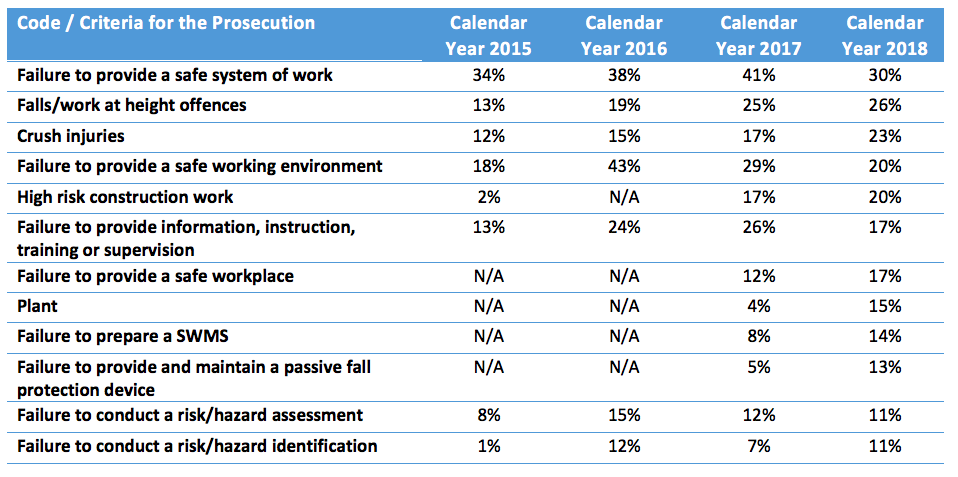

Prosecutions: What is the Cause and where are the Gaps?

With respect to the criteria/codes that lead to the prosecution – the criteria that was associated with 10% of the prosecutions in 2018, as defined by WorkSafe Victoria, are outlined below.

These criteria are relatively consistent with 2015 through to 2017. Both 2017 and 2018, have seen an increase in “construction- related” prosecutions, highlighted by the increase in “Falls/work at height offences”, “High risk construction work” along with the “Failure to prepare a SWMS”. This aligns with WorkSafe Victoria’s focus on high risk industries.

“Failure to provide a safe system of work” and “failure to provide a safe workplace” continues to places a clear duty on all workplaces to understand their operations, the hazards associated with their work, and ensure that the established controls are implemented.

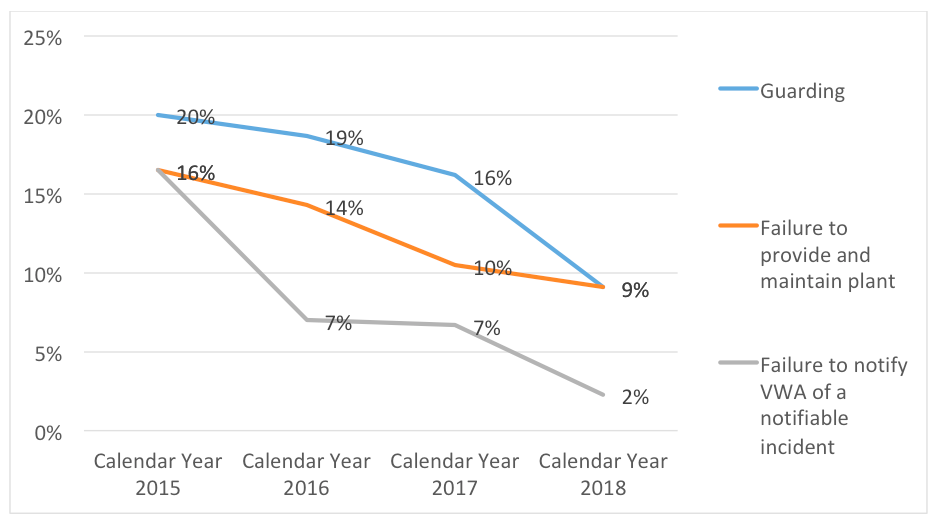

Other criteria noteworthy to report on includes reductions in prosecutions related to:

- Guarding

- Failure to provide and maintain plant

- Failure to notify WorkSafe Victoria of a notifiable incident

The Complimentary Support

Action OHS Consulting continues to observe a rise in inbound calls for support, associated with businesses wanting guidance, on how they can best manage their legal obligations associated with health and safety. As such, during late 2018 Action OHS Consulting developed and delivered a 4-part webinar series providing direction on this: The War on Safety. The good news is that it is free for you to download.

In addition, Action OHS Consulting is on a panel of providers endorsed by WorkSafe Victoria which provides complementary OHS Review’s for Victorian-based businesses with less than 60 workers across a period of 18-months. If you would like to find out more about this program, please contact us.

The Takeaway

The Health and Safety Legislation is risk-based and required businesses and their senior managers to understand and manage the hazards associated with their operations. Put simply, this leads to a requirement for workplaces to actively:

- Assess their workplace hazards. Consider listing all the you’re your workers could get hurt, and document what you have put in place to stop this from happening. If it feels hard, try listing the “Top 5” hazards – focusing on those which could cause the most serious harm. Look to do this with several workers, across different roles within your business. If you identify things that you could improve and/or do better, this is not bad, in fact, it is the point of the exercise.

- Establish an induction program. This may include a “buddy” being assigned to “new” and/or “young” workers. Ensure the induction includes an overview of your safety program and the operational activities that the worker will undertake.

- Ensure your implementation is sustainable. Don’t rely on just one person. Spreadsheets and folders can be effective if you are organised, however, are difficult to maintain visibility when tasks are due – or more importantly, when tasks are missed. Web-based platforms such as Safety Champion Software will support visibility of your health and safety program, guide and remind you when deadlines and key milestones approach.

- Considering safety when engaging contractors. Workplaces often engage contractors to support processes that the workplace is not familiar with, which often means new hazards are introduced to the workplace. Prior to engaging contractors, along with price, seek information from the contract to understand how they will help you maintain a safe working environment when they are onsite.

- Consider safety as part of your procurement process. Before you buy anything, consider the safety implications. Don’t limit this to equipment, machinery, computers – extended this to services as well. Don’t make safety an afterthought.

We would be interested to hear your thoughts, questions or fears.

If like us, you would like to interrogate data, we would be more than happy to share an unlocked copy of the data with you – simply Contact us.