Prosecutions: 2021 summary for NSW and Victoria

Business leaders have a legislative duty to acquire and maintain up-to-date knowledge of work health and safety matters relevant to the nature of their operations.

But without any visibility of the health and safety prosecutions that have occurred, it can be hard to grasp what could go wrong within your operations.

With a little context, you have an opportunity to reflect on current practices. This can help to ensure that reasonably practicable controls have been established, and to ensure ‘like’ or ‘now foreseeable’ incidents are less likely to occur within the workplace.

‘Reasonably practicable’ means that you should consider the likelihood and degree of harm of a hazard or risk. Whilst there may not have previously been an incident at your workplace, if a significant incident has occurred across your industry, you should be aware of it.

Each year, Action OHS Consulting collates and reviews the data available from both WorkSafe Victoria and SafeWork NSW. Used effectively, this information should support you to influence key stakeholders within your organisation, and assist your business to make informed decisions with respect to their health and safety program.

The prosecution data has been collated from:

- WorkSafe Victoria Prosecution Data

- SafeWork NSW Prosecution Data (this version was updated September 2022 – once prosecution data for October to December 2021 was made available by SafeWork NSW)

This article provides an overview of the prosecutions from 2015 through to the 2021 calendar years.

Prosecutions: Numbers and related legislation

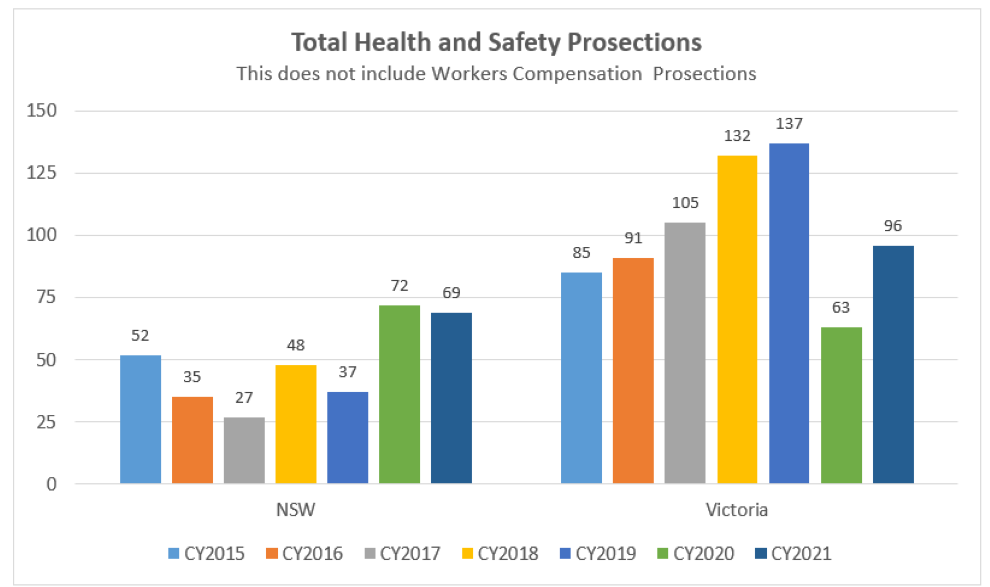

The 2021 calendar year saw a total of 96 prosecutions against the Victorian health and safety legislation, whilst in NSW the number of prosecutions was 69.

When compared to the previous year, there has been a 52% increase in Victoria and a 4% decrease in NSW. This is compared to a 54% increase and 95% decrease the year prior (CY2019 to CY2020) for both Victoria and NSW respective.

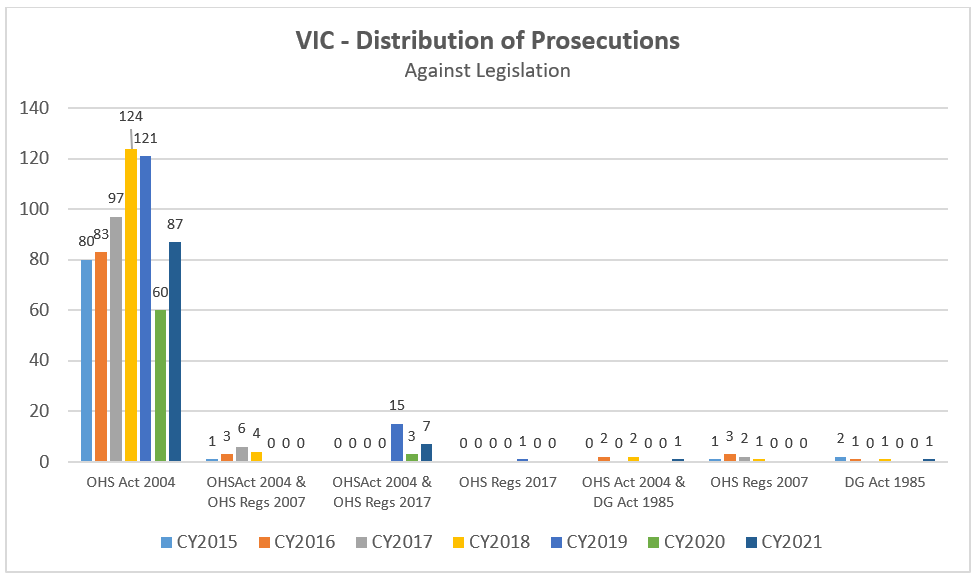

Within Victoria:

- 87 prosecutions were recorded against the Occupational Health and Safety Act 2004 only

- 1 prosecution was recorded against the Dangerous Goods Act 1985 only

- 7 prosecutions involved both the Occupational Health and Safety Act 2004 and the Occupational Health and Safety Regulations 2017

- 1 prosecution involved both the Occupational Health and Safety Act 2004 and the Dangerous Goods Act 1985

Unlike previous years, no prosecution involved the Occupational Health and Safety Regulations 2017 only.

Zero prosecutions were against the 2007 version of the Occupational Health and Safety Regulations which were updated in 2017.

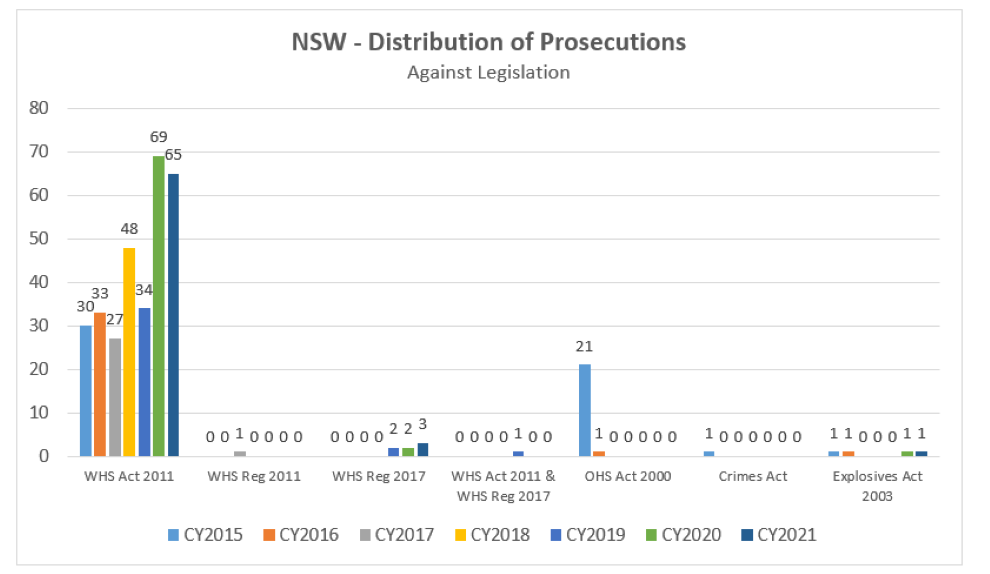

Within NSW:

- 65 prosecutions were recorded against the Work Health and Safety Act 2011 only

- 3 prosecution was recorded against the Work Health and Safety Regulation 2017 only

- 1 prosecution involved the Explosives Act 2003

Prosecution timeframes

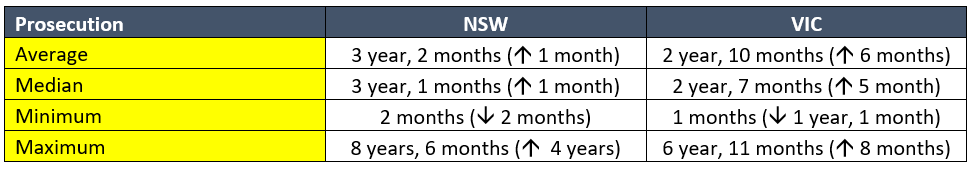

The table below lists the timeframe for the prosecution’s outcomes from 2021 when measured against the date of the offence.

Table 1: Timeframe between date of offence and the prosecution outcome, for the 2021 prosecution outcomes reported by SafeWork NSW & WorkSafe Victoria. Bracketed numbers represent the increase / decrease from 2020.

Health and safety fines

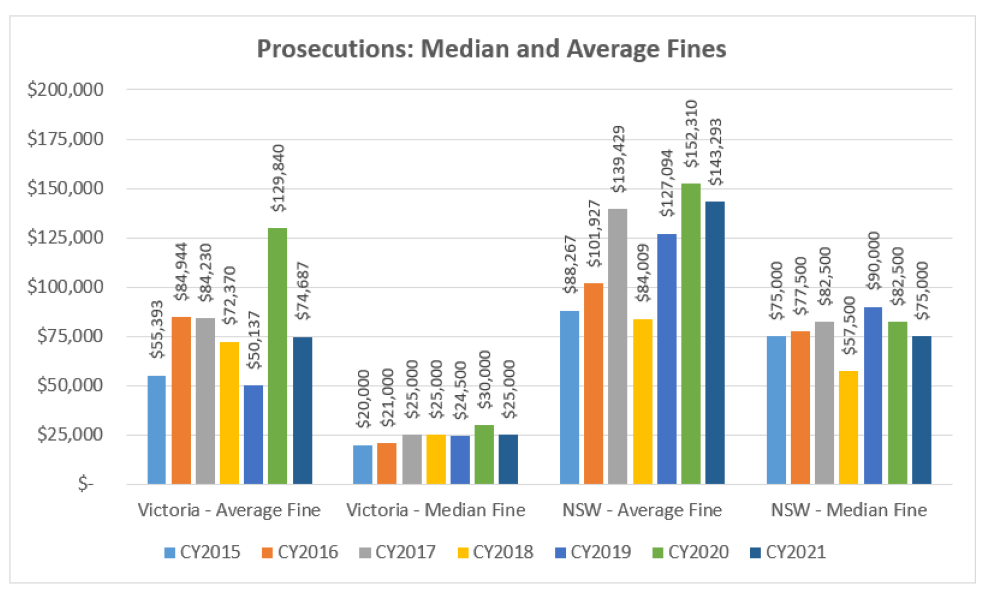

Year on year, the average fine and median fine in Victoria and in NSW remained consistent with previous years. The average and median fines were greater in NSW, when compared to Victoria.

In NSW all but one prosecution resulted in a monetary fine. In the one prosecution that didn’t involve a fine, the Director was required to enter a Work Health and Safety undertaking. The company was fined $75,000.

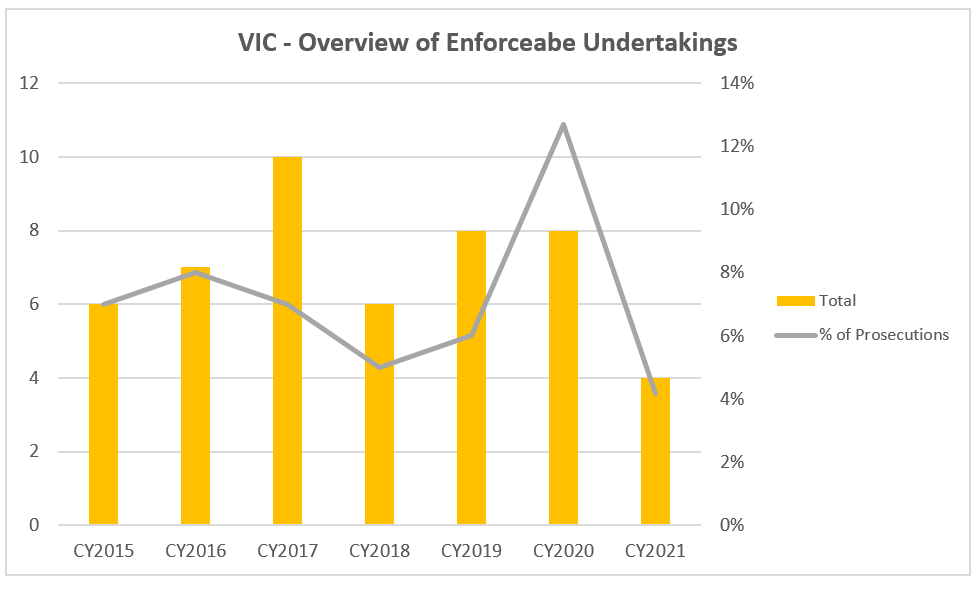

In Victoria 88 fines were issued (92% of prosecutions). In addition to the fines, WorkSafe Victoria issued 4 Enforceable Undertakings in 2021 which equates to 4% of prosecutions. This is compared to the 8 (13%) Enforceable Undertaking issued in 2020.

An ‘enforceable undertaking’ (EU) is a legally binding agreement between WorkSafe Victoria and the employer. The employer is obliged to carry out the specific activities outlined in the agreed undertaking. EUs will typically guide and direct the business being prosecuted to improve its health and safety program.

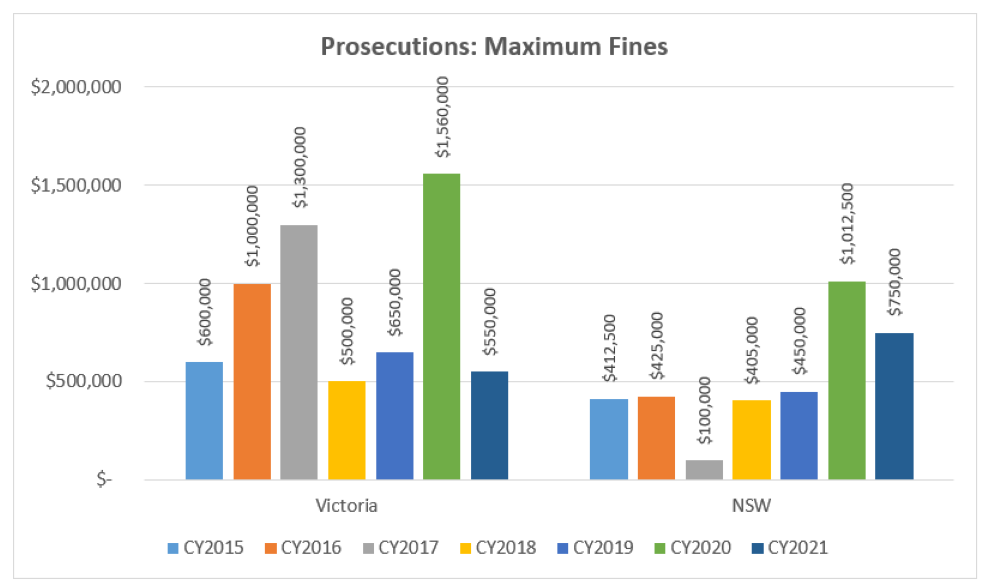

Health and safety fines: Maximum issued

With respect to fines, the maximum fines for both Victoria and NSW decreased year on year. The fines issued in 2020 were the greatest in each jurisdiction since 2016.

The maximum fines issued to a business were associated with the following events:

Victoria: The offender was a civil construction company based in Delacombe. In January 2018 the offender entered into a contract to construct a main trunk sewer system for a housing development. On 20 March 2018, a supervisor employed by the offender told the crew to get a manhole ready for a stub branch on the following day, while the supervisor continued working on manholes more than half a kilometre away. The terrain between the two locations was undulating. On 21 March 2018, a labourer and pipe layer, and 21 year-old labourer, employed by the offender, were instructed by the supervisor to work at the manhole more than half a kilometre from the supervisor. The two employees commenced the task, speaking with the supervisor on three occasions during the morning. At 10 am the supervisor and other employees met at the break room for smoko, however the two employees did not join them. At no point during the morning of 21 March 2018 did the supervisor either check how the work was being carried out or ensure that a manhole cage and/or a trench shield had been installed in the excavation before any high-risk work commenced.

If appropriate safety measures were not used, there was a risk that a trench or manhole pit could collapse while the offender’s employees were carrying out this high-risk work and could thereby be injured or killed. The offender failed to provide the supervision that was necessary to enable its employees to perform their work in a way that was safe and without risks to their health.

At approximately 11 am two subcontractors arrived at the manhole and saw that the manhole had collapsed. One employee of the offender was buried to the extent that only his head and one arm was showing. He communicated to the subcontractors to get him out of the trench. The other employee in the trench was not moving and was not responsive. Emergency Services was called, and the offender’s employees attempted to dig the two buried employees out using their hands, shovels and an excavator. When Emergency Services arrived one employee was extracted from the collapsed trench and taken to hospital, where he died from his injuries including metabolic derangement and multiple organ failure the following day. The other employee died from head injuries at the scene.

The offender pleaded guilty and was with conviction sentenced to pay a fine of $550,000.

In sentencing the Court took into consideration:

- the objective seriousness of the offence was relatively high

- Victim Impact Statements from family and friends of both deceased employees

- the offender’s history as an employer, and its lack of prior convictions

- the offender’s plea of guilty and the enhanced utilitarian value of a guilty plea during COVID delay, some of which was not attributable to the offender

- media coverage of the incident and the impact it had on the offender’s reputation, and

- that a conviction may impact the offender’s prosperity in future, particularly in respect of tendering for government contracts

NSW: On 3 July 2018, a volunteer from a Men’s Shed volunteer organisation was laying pipe for water irrigation system at Camden Bicentennial Equestrian Park when the pipe moved over the star picket and struck him on the head, causing fatal injuries. After a SafeWork NSW investigation, the defendant, Camden Council, was charged with breaches of section 32/19(1) of the Work Health and Safety Act 2011. On 21 December 2021, the defendant was convicted by the District Court and fined $750,000.

It is not just businesses being prosecuted in relation to health and safety breaches

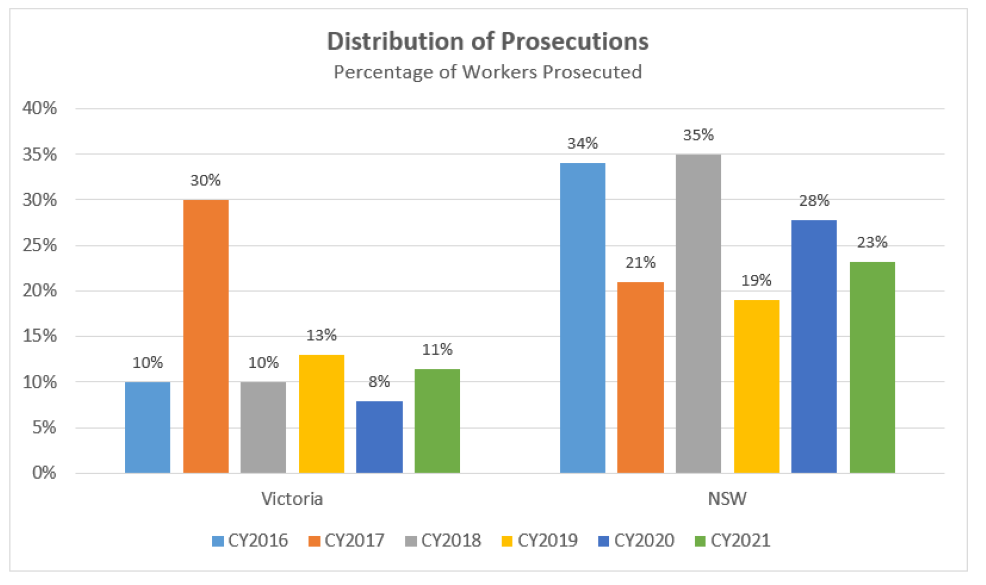

Health and safety prosecutions are not limited to corporations. In 2021, 11% and 23% of prosecutions were issued to workers in Victoria and NSW respectively – equating to 11 and 16 prosecutions respectively.

The maximum fine issued to workers in Victoria and NSW in 2021 was $176,750 and $150,000 respectively. Whilst the average fine in Victoria and NSW was $41,678 and $32,369 respectively.

Prosecutions: What is the cause and where are the gaps?

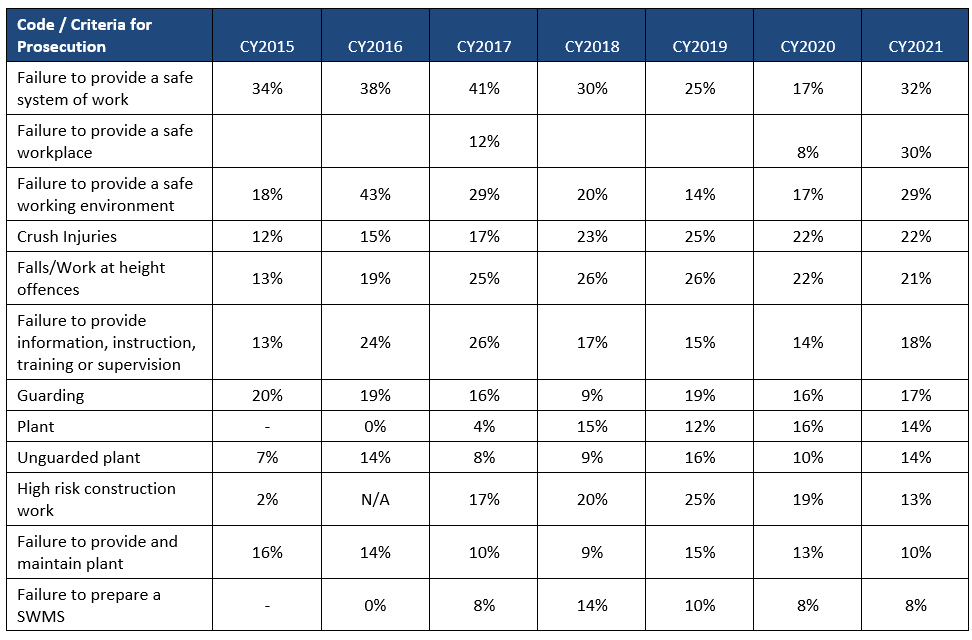

With respect to the criteria/codes that lead to the prosecution – of the 55 criteria that were referenced, the top 12 criteria associated with prosecutions in 2021, as defined by WorkSafe Victoria, are outlined below.

These criteria are relatively consistent since 2015.

‘Failure to provide a safe system of work’ continues to places a clear duty on all workplaces to understand their operations, the hazards associated with their work, and ensure that the established controls are implemented.

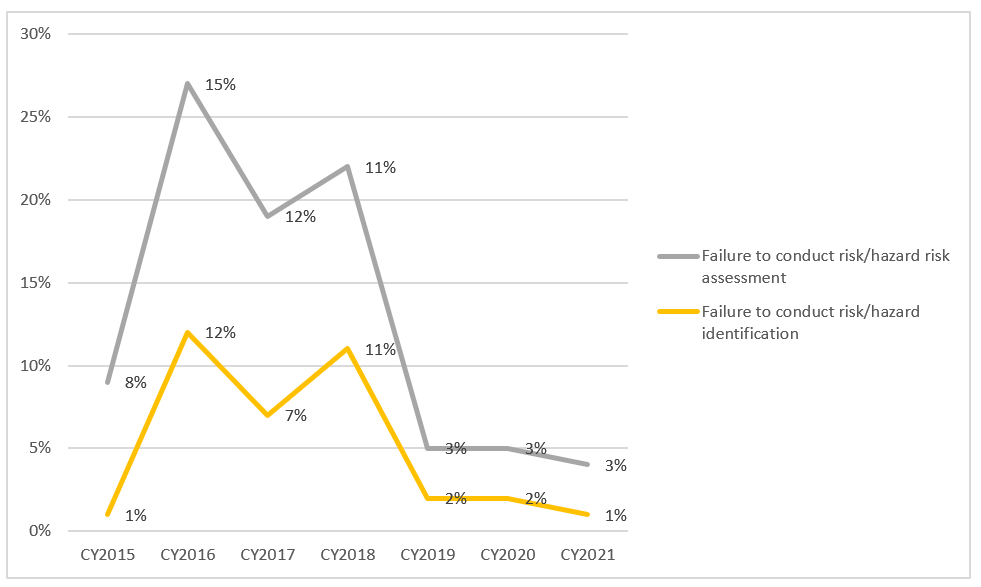

Other noteworthy criteria includes reductions in prosecutions related to failure to conduct risk/hazard identification or risk assessment:

Health check

Action OHS Consulting, in collaboration with its sister-company Safety Champion Software, has developed a self-assessment tool: Safety Champion Impact Assessment. This tool has been designed to support businesses to understand potential points of failure, allowing them to proactively improve their health and safety program. You can access this tool for free up until December 2022.

START SAFETY CHAMPION IMPACT ASSESSMENT

Free webinar support

Action OHS Consulting developed and delivered a four-part webinar series providing direction on how businesses can best manage their legal obligations associated with health and safety.

The good news is that it is free for you to download.

DOWNLOAD THE WAR ON SAFETY WEBINAR SERIES

Key takeaways

To allow better and more informed decisions to be made, businesses must have established processes to understand how effectively their health and safety program has been implemented.

The Health and Safety Legislation adopts a self-regulated risk-based approach. This means businesses and their leaders are required to understand what could foreseeably go wrong within their operations, and then establish reasonably practicable controls to minimise the likelihood or severity of such events occurring. The intention; is to protect workers, contractors, customers and visitors from harm.

This requires leaders to be real. It requires them to appreciate that safety as documented by your policy and procedure manual, may not reflect work as completed operationally. Put simply, this leads to a requirement for workplaces to actively:

- Ensure that your safety program is easy to access and understand, and importantly relevant to your operations. Strongly consider implementing safety software such as Safety Champion, to help ensure that scheduled tasks are completed, and that workers can easily report incidents and/or hazards. Ensuring that you have visibility and ready access to this information, will assist you to proactively prevent incidents from occurring in the future.

- List all the ways your workers could get hurt, and document what you have put in place to stop this from happening. Start by listing the “Top 5” hazards – focusing on those which could cause the most serious harm. Do this in consultation with a selection of workers who hold different roles within your business. If you identify things that you could improve and/or do better, this is not bad, in fact, it is the point of the exercise.

- Continue to consult. Have regular structured and unstructured conversations with your team regarding the controls you have established.

- Build competency. Ensure that you have an induction program that includes an overview of your safety program and the operational activities that the worker will undertake. Consider assigning a buddy to new and/or young workers.

- Ensure your safety program is sustainable. Don’t rely on just one person. Spreadsheets and folders can be effective if you are organised, however, are difficult to maintain visibility when tasks are due – or more importantly, when tasks are missed. Again, this is where software programs like Safety Champion Software will support your organisation, providing visibility of your health and safety program in real-time, remind you when deadlines and key milestones approach, and provide you with access to data to make data-based decisions.

- Consider safety as part of your procurement process. Before you buy anything, consider the safety implications. Don’t limit this to equipment, machinery, computers – extended this to services as well. Don’t make safety an afterthought.

We would be interested to hear your thoughts, questions or concerns.

If like us, you would like to interrogate data, we would be more than happy to share an unlocked copy of the data with you – simply Contact Us.